3d printing is different from cnc machining and milling

When it comes to creating physical prototypes, there are several different methods available. Two of the most popular options are 3D printing and subtractive rapid prototyping, which includes CNC machining or milling. While both methods can be used to create high-quality prototypes, they differ significantly in their approach.

3D Printing

3D printing, also known as additive manufacturing, involves building up an object layer by layer using a digital 3D model as a blueprint. The printer starts with a base layer of material, usually plastic or resin, and then adds successive layers until the object is complete. This process allows for complex and intricate designs to be created quickly and easily. There are many different types of 3D printers, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

One of the primary advantages of 3D printing is its speed and ease of use. It is relatively simple to create a digital model of a design, and the printer can create a physical version of that model in just a few hours. This makes it an ideal choice for rapid prototyping and allows designers to test out multiple iterations of a design quickly.

Another benefit of 3D printing is its ability to create complex shapes and designs that would be difficult or impossible to produce with traditional manufacturing methods. 3D printers can create objects with intricate internal structures or overhangs, making them a popular choice for prototyping parts for the aerospace, automotive, and medical industries.

Subtractive Rapid Prototyping

Subtractive rapid prototyping, also known as CNC machining or milling, is a process where a solid block of material, such as metal or plastic, is cut away using a computer-controlled machine to create a specific shape or design. The machine removes material from the block until the desired shape is achieved. This process is ideal for creating parts with high precision and accuracy.

Unlike 3D printing, subtractive rapid prototyping requires more setup time and expertise.

A digital model of the design is still required, but the process of programming the machine to cut away the material can be complex and time-consuming. However, once the setup is complete, the machine can produce parts quickly and accurately.

One of the benefits of subtractive rapid prototyping is the ability to create parts from a wide range of materials, including metals and plastics. This makes it an ideal choice for creating functional prototypes for mechanical components.

Comparison between 3d printing and machining

Both 3D printing and subtractive rapid prototyping have their advantages and disadvantages. 3D printing is faster and easier to set up, making it ideal for creating complex shapes and testing multiple design iterations quickly.

However, 3D printing can produce parts with lower accuracy and may not be suitable for creating functional prototypes.

Subtractive rapid prototyping, on the other hand, is more precise and accurate and can produce functional prototypes from a wide range of materials. However, it requires more setup time and expertise and may not be suitable for creating complex shapes or intricate designs.

Ultimately, the choice between 3D printing and subtractive rapid prototyping depends on the specific needs of the project. Designers should consider factors such as the required precision and accuracy, the complexity of the design, and the materials used to determine which method is the best fit.

Do you need a cnc machined model? What are the preparations to get a machined prototype?

When

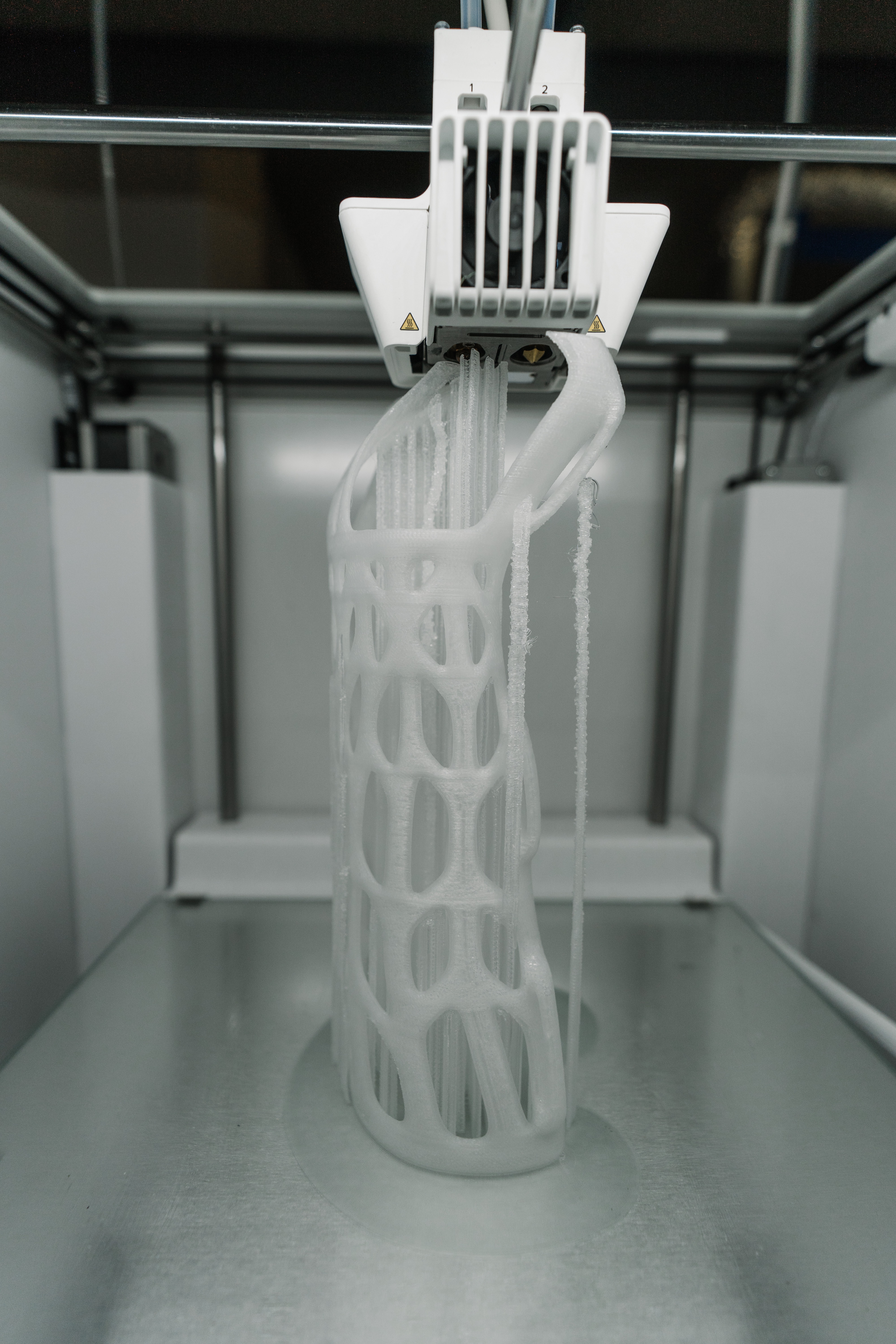

A 3d printing example

When you designed a pieces of art, or a complicated part, 3d printing can do the job. Here-above you see a picture of a 3d part made of white ABS.

CNC machined examples

Folks have fought some monster bluefin tuna on standup gear with our offshore fishing packager, which is an incredible challenge for sure! Stick to the shoreline and test your strength pulling in some biggies!